There’s an art to translating Elon’s commentary into Tesla’s projected quarterly results. This art should be complemented with some science.

There are four key steps in reaching a conclusion:

- At the highest level, Elon has been clear that the June quarter will be “tough.”

- Elon has announced the company is laying off 10% of salaried staff while at the same time increasing hours for the manufacturing line.

- In June 2022, Tesla raised prices on six of their nine trims by an average of 4%. This is on top of a price increase impacting two models in April at an average of 2.5%, and all models in March at an average of 9%. In other words, since October of 2021, Tesla has raised prices by an average of 10%. Since last June, prices increased by an average of 18%.

- Average lead times for Models 3 and Y have increased by roughly 10% since April to the current 8.5 months. Models S and X had a lead time increase of 12% in the past two months, now averaging at 12 month lead times.

Interpreting the art and science

My bottom line: the Shanghai shutdown will likely negatively impact June deliveries by about 8%. For the September quarter, we expect the company to strike a cautionary tone based on the macro unknowns. As a testimony to the unknowns, Honda’s US industry was down 57% in the month of May. That said, I expect Tesla to repeat their eight-year 50% compound delivery growth target.

Laying off 10% of salaried staff

On June 3rd, Elon announced he is prepared to lay off of 10% of salaried workers and increase production of hourly employees. Elon appears to be on a productivity binge, based upon his request that salaried workers return to the office and his commentary that staff cuts are on the horizon. While Tesla is new to this approach, the concept of reducing the bottom 10% of the workforce is an accepted approach to management. As for the increase in production hours, a logical interpretation is that demand for Tesla vehicles remains healthy.

Price increases are adding up

Tesla continues to raise prices despite Elon’s commentary that it will be a tough quarter for the company. Since October, Tesla has raised car prices 3 times, averaging at a total increase of 18% (including the recent March and June quarters). I expect the profit of said price increases to offset increasing component costs. Regardless of where the additional revenue will be applied to, it is unlikely that the company would raise prices for any reason if demand was softening.

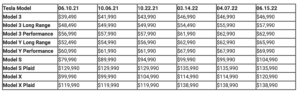

The table below outlines the price increases over the past year:

Lead times increasing

We track lead times on a monthly basis for nine Tesla trims in eight countries (US, China, Germany, Netherlands, Denmark, UK, Mexico and Japan), and we have found lead times to be increasing across the board. What’s most important are the lead times for the Model 3 and Model Y given they account for about 90% of Tesla’s overall revenue. Average lead times for these models have increased about 10% since April, now averaging at about 8.5 months. Our observations of Model S and Model X show lead times increasing by 12% over the past two months, now at about 12 months.